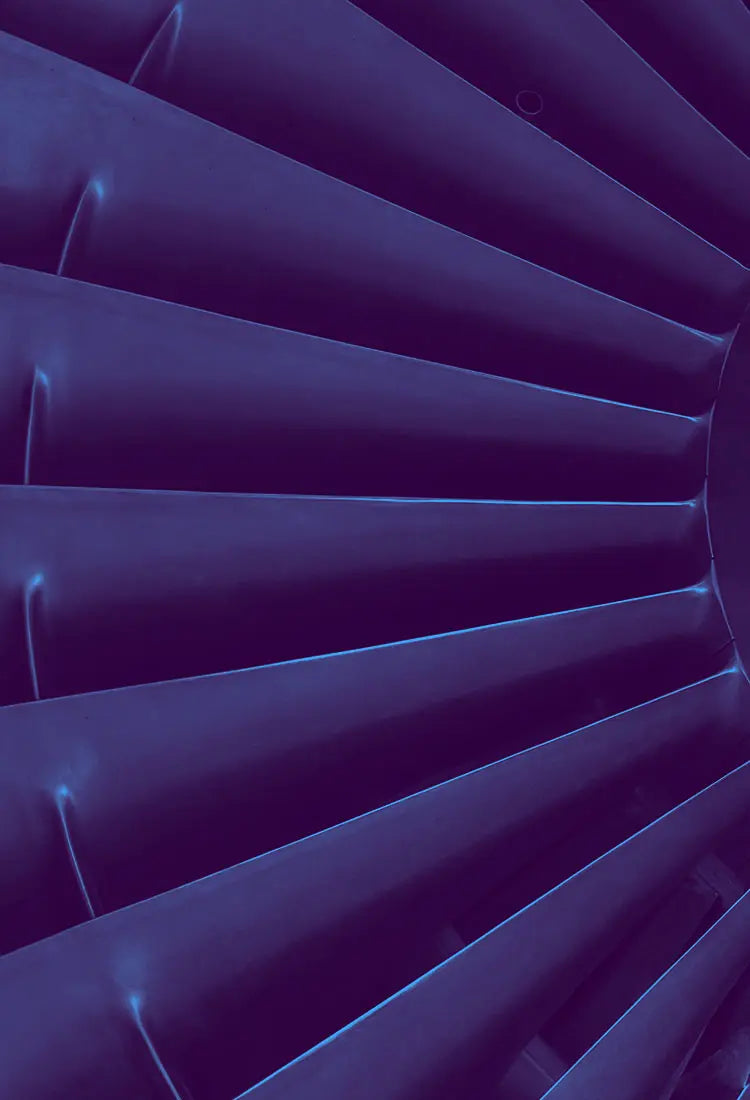

Turbine Blade Casting Inspection

Turbine blade castings, often made from nickel-based alloys like stainless steel via investment casting, require precise manufacturing processes. This method involves creating a wax prototype, coating it in liquid ceramics, and then removing the wax to leave a ceramic mold.

These complex components, including combustors, air compressors, and fuel injectors, feature intricate internal cavities demanding remote visual inspections to meet the stringent quality standards of aerospace/aviation OEMs.

These inspections ensure the absence of cracks, porosity, and metal burrs, aligning with most manfacturers' Quality Management Systems. InterTest, Inc. provides advanced inspection tools for such remote examinations, essential for the thorough documentation and verification of component integrity.

Turbine Blade Casting Inspection

Learn how InterTest, Inc. products are involved in the daily qualtoy assurance procedures of the airfoil and turbine balde casting industry. Call InterTest, Inc. today for a free consultation on your turbine blade inspection application.

Contact Us